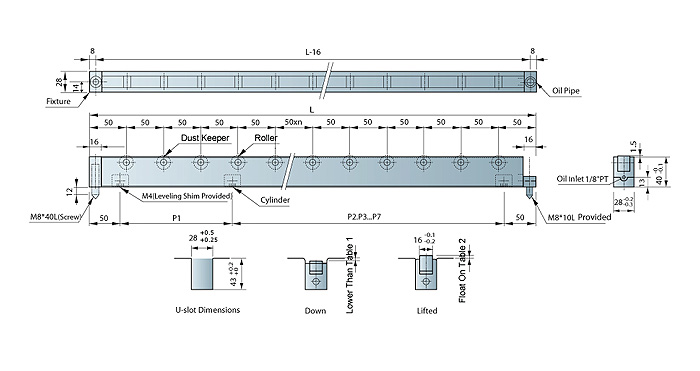

DL Die Lifter (Roller Type)

Die Lifters

The Quick Die Change System caters for a variety of different Die Lifters which allow for simple and quick movement of dies on a press bed. Forwell supplies two different types of Die Lifters according to the press tonnage, die weight and the die positioning accuracy required. There is a choice between a Spring-Loaded Die Lifter, better suited for light to medium duty pressing operations and a Hydraulic Die Lifter more often used for medium to heavy duty pressing.

Introduction

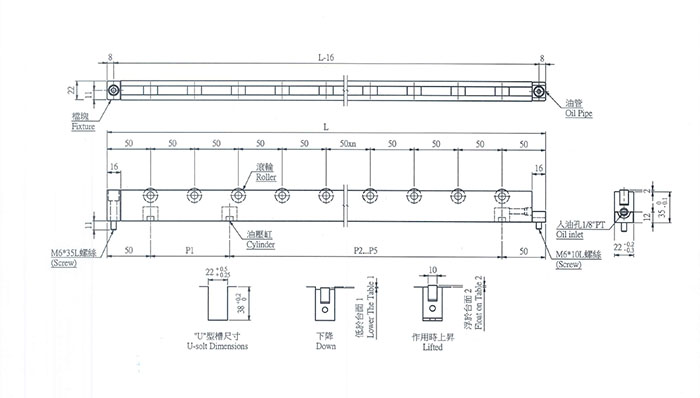

The hydraulic DL type Die Lifter is designed for very heavy duty dies and very heavy load weights. The scrap guard/scrapers keep the roller surfaces free from scraps and the rollers are arranged tightly into the bolster to prevent damage to the bottom of heavy dies. The height of the roller can be adjusted by replacing some of the built-in shims with different thicknesses.

DL-22

| Model | Overall | Roller Q'ty | Load Capacity | Lift Cylinder (kg) | |

|---|---|---|---|---|---|

| Pcs | Lift Farce | ||||

| DL-22-300 | 300 | 5 | 300 | 2 | 500 |

| DL-22-400 | 400 | 7 | 420 | 3 | 750 |

| DL-22-500 | 500 | 9 | 540 | 4 | 1000 |

| DL-22-600 | 600 | 11 | 660 | 5 | 1250 |

| DL-22-700 | 700 | 13 | 780 | 5 | 1250 |

| DL-22-800 | 800 | 15 | 900 | 6 | 1500 |

| Model | Lift Cylinder Pitch (mm) | ||||

|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | P5 | |

| DL-22-300 | 200 | ||||

| DL-22-400 | 90 | 210 | |||

| DL-22-500 | 90 | 220 | 90 | ||

| DL-22-600 | 90 | 160 | 160 | 90 | |

| DL-22-700 | 90 | 210 | 210 | 90 | |

| DL-22-800 | 90 | 220 | 220 | 150 | 90 |

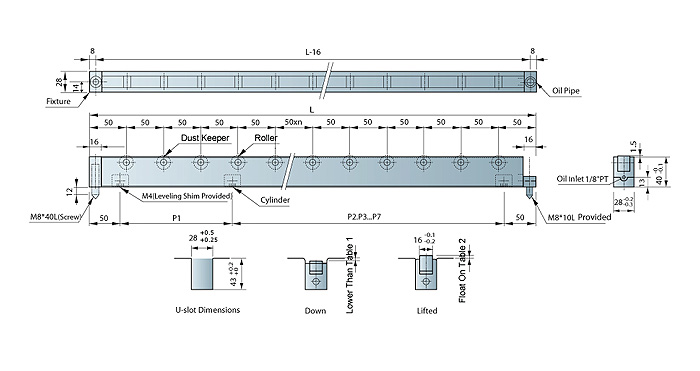

DL-28

| Model | Overall | Roller Q'ty | Load Capacity | Lift Cylinder (kg) | |

|---|---|---|---|---|---|

| Pcs | Lift Farce | ||||

| DL-28-400 | 400 | 7 | 560 | 2 | 1000 |

| DL-28-500 | 500 | 9 | 720 | 3 | 1500 |

| DL-28-600 | 600 | 11 | 880 | 4 | 2000 |

| DL-28-700 | 700 | 13 | 1040 | 4 | 2000 |

| DL-28-800 | 800 | 15 | 1200 | 5 | 2500 |

| DL-28-900 | 900 | 17 | 1360 | 5 | 2500 |

| DL-28-1000 | 1000 | 19 | 1520 | 6 | 3000 |

| DL-28-1100 | 1100 | 21 | 1680 | 6 | 3000 |

| DL-28-1200 | 1200 | 23 | 1840 | 7 | 3500 |

| DL-28-1300 | 1300 | 25 | 2000 | 7 | 3500 |

| DL-28-1400 | 1400 | 27 | 2160 | 8 | 4000 |

| DL-28-1500 | 1500 | 29 | 2320 | 8 | 4000 |

| Model | Lift Cylinder Pitch (mm) | ||||||

|---|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | |

| DL-28-400 | 300 | ||||||

| DL-28-500 | 90 | 310 | |||||

| DL-28-600 | 100 | 340 | 60 | ||||

| DL-28-700 | 150 | 350 | 100 | ||||

| DL-28-800 | 95 | 95 | 390 | 120 | |||

| DL-28-900 | 110 | 110 | 410 | 170 | |||

| DL-28-1000 | 130 | 130 | 420 | 110 | 110 | ||

| DL-28-1100 | 150 | 150 | 460 | 120 | 120 | ||

| DL-28-1200 | 100 | 150 | 150 | 200 | 200 | 200 | |

| DL-28-1300 | 150 | 150 | 300 | 300 | 150 | 150 | |

| DL-28-1400 | 100 | 100 | 150 | 150 | 200 | 250 | 350 |

| DL-28-1500 | 100 | 100 | 150 | 150 | 200 | 350 | 350 |

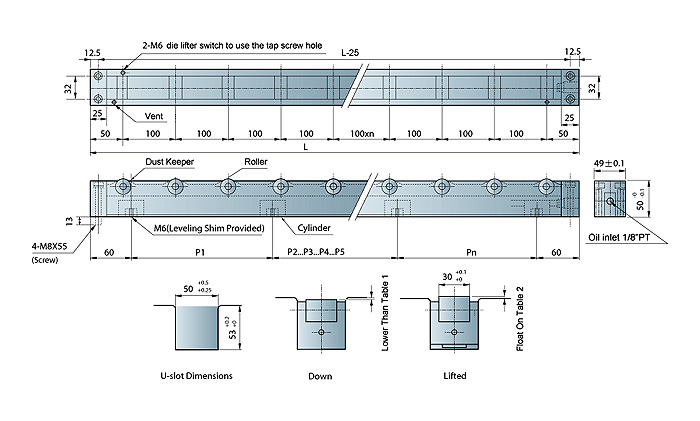

DL-50

| Model | Overall | Roller Q'ty | Load Capacity | Lift Cylinder (kg) | |

|---|---|---|---|---|---|

| Pcs | Lift Farce | ||||

| DL-50-400 | 400 | 4 | 800 | 2 | 2200 |

| DL-50-500 | 500 | 5 | 1000 | 3 | 3300 |

| DL-50-600 | 600 | 6 | 1200 | 4 | 4400 |

| DL-50-700 | 700 | 7 | 1400 | 4 | 4400 |

| DL-50-800 | 800 | 8 | 1600 | 4 | 4400 |

| DL-50-900 | 900 | 9 | 1800 | 4 | 4400 |

| DL-50-1000 | 1000 | 10 | 2000 | 5 | 5500 |

| DL-50-1100 | 1100 | 11 | 2200 | 5 | 5500 |

| DL-50-1200 | 1200 | 23 | 4600 | 5 | 5500 |

| DL-50-1300 | 1300 | 25 | 5000 | 6 | 6600 |

| DL-50-1400 | 1400 | 27 | 5400 | 6 | 6600 |

| DL-50-1500 | 1500 | 29 | 5800 | 7 | 7700 |

| DL-50-1600 | 1600 | 31 | 6200 | 7 | 7700 |

| DL-50-1700 | 1700 | 33 | 6600 | 8 | 8800 |

| DL-50-1800 | 1800 | 35 | 7000 | 8 | 8800 |

Note: For purchases please attach a bolster plate diagram for correct sizing of the waste material hole at the bottom

| Model | Lift Cylinder Pitch (mm) | ||||||

|---|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | |

| DL-50-400 | 280 | ||||||

| DL-50-500 | 90 | 290 | |||||

| DL-50-600 | 90 | 330 | 60 | ||||

| DL-50-700 | 140 | 340 | 100 | ||||

| DL-50-800 | 170 | 390 | 120 | ||||

| DL-50-900 | 210 | 400 | 170 | ||||

| DL-50-1000 | 125 | 125 | 410 | 220 | |||

| DL-50-1100 | 150 | 150 | 400 | 280 | |||

| DL-50-1200 | 150 | 150 | 400 | 380 | |||

| DL-50-1300 | 150 | 150 | 200 | 400 | 280 | ||

| DL-50-1400 | 150 | 150 | 200 | 400 | 380 | ||

| DL-50-1500 | 150 | 150 | 200 | 300 | 300 | 280 | |

| DL-50-1600 | 100 | 150 | 250 | 400 | 300 | 280 | |

| DL-50-1700 | 100 | 100 | 150 | 250 | 300 | 300 | 380 |

| DL-50-1800 | 100 | 100 | 150 | 250 | 300 | 300 | 480 |

Note: For purchases please attach a bolster plate diagram for correct sizing of the waste material hole at the bottom

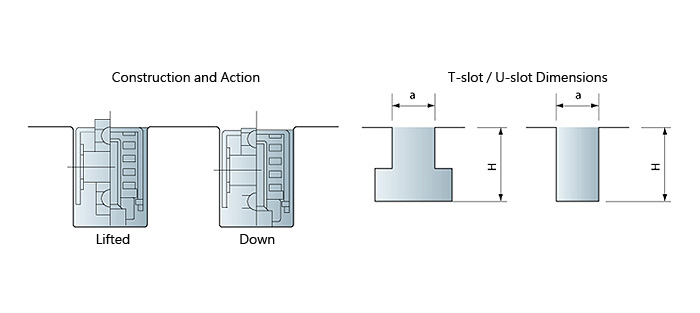

Die Lifters

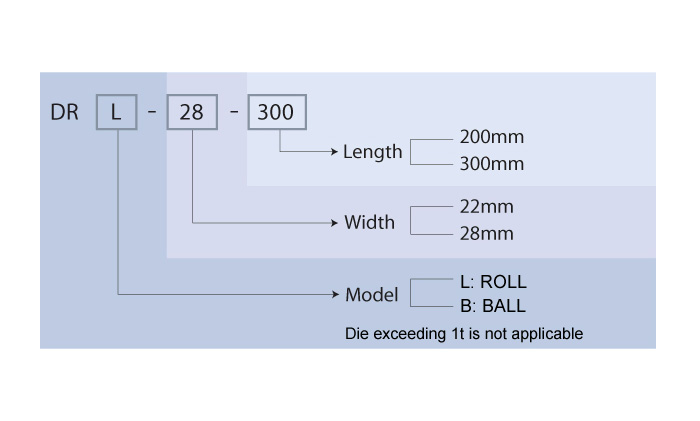

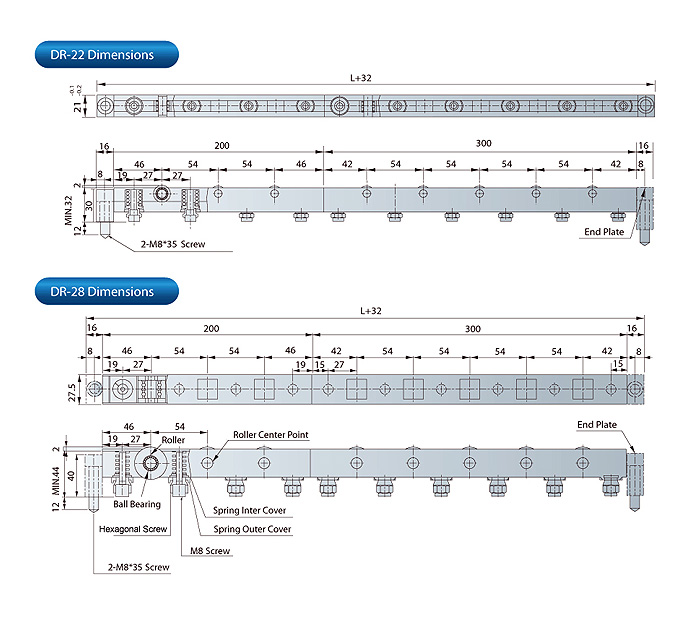

These Spring-Loaded Die Lifters easily slide into different sized T or U-slots on the bolster by adding spacers to the side walls of the Die Lifters. This allows for accurate and easy die positioning as well as quick and easy die removal. The DR Series Die Lifters are available in customizable lengths in increments of 100mm, and are available as either a ball type lifter or roller type lifter.

DR Diagram

| Model | a | H |

|---|---|---|

| DR-22 | 22 | 33-43 |

| DR-28 | 28 | 45-58 |

DR Specifications

| Basic Model | Width (mm) | Length (mm) | Springs (pcs) | Lift Farce (kgf) |

|---|---|---|---|---|

| DRL-22-200/DRB22-200 | 22 | 200 | 4 | 37.5 |

| DRL-22-300/DRB22-300 | 22 | 300 | 6 | 37.5 |

| DRL-28-200/DRB28-200 | 28 | 200 | 4 | 75 |

| DRL-28-300/DRB28-300 | 28 | 300 | 6 | 75 |

Maximum lift force per line (kgf)

| mm kgf Model |

200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

|---|---|---|---|---|---|---|---|---|---|

| DR-22 | 150 | 225 | 300 | 375 | 450 | 525 | 600 | 675 | 750 |

| DR-28 | 300 | 450 | 600 | 750 | 900 | 1050 | 1200 | 1350 | 1500 |

Maximum lift force per line (kgf)

| mm kgf Model |

1100 | 1200 | 1300 | 1400 | 1500 | 1600 | 1700 | 1800 | 1900 | 2000 |

|---|---|---|---|---|---|---|---|---|---|---|

| DR-22 | 825 | 900 | 975 | 1050 | 1125 | 1200 | 1275 | 1350 | 1425 | 1500 |

| DR-28 | 1650 | 1800 | 1950 | 2100 | 2250 | 2400 | 2550 | 2700 | 2850 | 3000 |

DB28 Die Lifter (Ball Type)

The hydraulic DB Die Lifter employs universal bearings for superior forward and reverse, left and right motion of molds in and out of press machines.

DB-28

| Model | Overall | Ball Q'ty | Lift Cylinder | Lift Cylinder Pitch (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pcs | Lift Farce | P1 | P2 | P3 | P4 | P5 | P6 | P7 | |||

| DB-28-400 | 400 | 7 | 2 | 1000 | 300 | ||||||

| DB-28-500 | 500 | 9 | 3 | 1500 | 90 | 310 | |||||

| DB-28-600 | 600 | 11 | 4 | 2000 | 100 | 340 | 60 | ||||

| DB-28-700 | 700 | 13 | 4 | 2000 | 150 | 350 | 100 | ||||

| DB-28-800 | 800 | 15 | 5 | 2500 | 95 | 95 | 390 | 120 | |||

| DB-28-900 | 900 | 17 | 5 | 2500 | 110 | 110 | 410 | 170 | |||

| DB-28-1000 | 1000 | 19 | 6 | 3000 | 130 | 130 | 420 | 110 | 110 | ||

| DB-28-1100 | 1100 | 21 | 6 | 3000 | 120 | 120 | 460 | 150 | 150 | ||

| DB-28-1200 | 1200 | 23 | 7 | 3500 | 300 | 200 | 200 | 150 | 150 | 100 | |

| DB-28-1300 | 1300 | 25 | 7 | 3500 | 150 | 150 | 300 | 300 | 150 | 150 | |

| DB-28-1400 | 1400 | 27 | 8 | 4000 | 350 | 250 | 200 | 150 | 150 | 100 | 100 |

| DB-28-1500 | 1500 | 29 | 8 | 4000 | 350 | 350 | 200 | 150 | 150 | 100 | 100 |

For purchases please attach a bolster plate diagram for correct sizing of the waste material hole at the bottom.

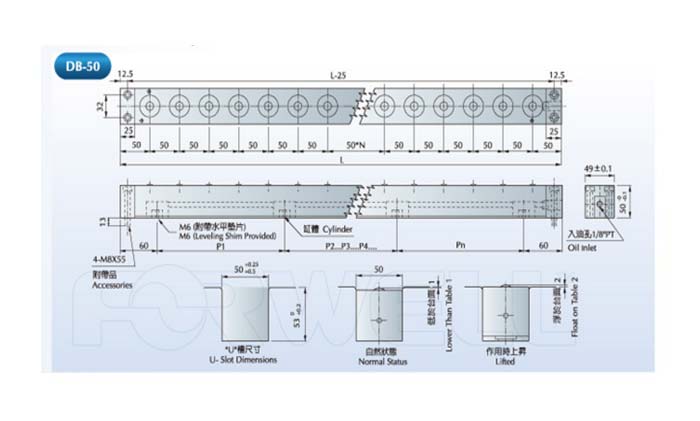

DB50 Die Lifter (Ball Type)

The hydraulic DB Die Lifter employs universal bearings for superior forward and reverse, left and right motion of molds in and out of press machines.

DB-50

| Model | Overall | Ball Q'ty | Lift Cylinder | Lift Cylinder Pitch (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pcs | Lift Farce | P1 | P2 | P3 | P4 | P5 | P6 | P7 | |||

| DB-50-400 | 400 | 7 | 2 | 2200 | 300 | ||||||

| DB-50-500 | 500 | 9 | 3 | 3300 | 90 | 290 | |||||

| DB-50-600 | 600 | 11 | 4 | 4400 | 90 | 330 | 60 | ||||

| DB-50-700 | 700 | 13 | 4 | 4400 | 140 | 340 | 100 | ||||

| DB-50-800 | 800 | 15 | 4 | 4400 | 170 | 390 | 120 | ||||

| DB-50-900 | 900 | 17 | 4 | 4400 | 210 | 400 | 170 | ||||

| DB-50-1000 | 1000 | 19 | 5 | 5500 | 125 | 125 | 410 | 220 | |||

| DB-50-1100 | 1100 | 21 | 5 | 5500 | 150 | 150 | 400 | 280 | |||

| DB-50-1200 | 1200 | 23 | 5 | 5500 | 150 | 150 | 400 | 380 | |||

| DB-50-1300 | 1300 | 25 | 6 | 6600 | 150 | 150 | 200 | 400 | 280 | ||

| DB-50-1400 | 1400 | 27 | 6 | 6600 | 150 | 150 | 200 | 400 | 380 | ||

| DB-50-1500 | 1500 | 29 | 7 | 7700 | 150 | 350 | 200 | 300 | 300 | 280 | |

| DB-50-1600 | 1600 | 31 | 7 | 7700 | 100 | 150 | 250 | 400 | 300 | 280 | |

| DB-50-1700 | 1700 | 33 | 8 | 8800 | 100 | 100 | 150 | 250 | 300 | 300 | 380 |

| DB-50-1800 | 1800 | 35 | 8 | 8800 | 100 | 100 | 150 | 250 | 300 | 300 | 480 |

For purchases please attach a bolster plate diagram for correct sizing of the waste material hole at the bottom.