Mold Handling for Injection Molding Machinery

When planning the purchase of your next plastic injection molding machine or even injection molding production line, one key issue is the problem of mold handling. With large plastic injection molding machinery, mold changing can take hours and consume a lot of costly manpower. By using Forwell’s specially designed quick mold change clamps, mold changes can take just a matter of minutes. Besides the huge time savings and reductions in labor costs, mold handling has become much safer and easier, in part because of the mold standardization used across the various mold handling systems.

Furthermore in order to suit a wide range of different systems, Forwell can fully customize the quick mold change system to fit any plastic injection molding machine. Mold handling can also be fully automated when combining a quick mold change system with one of Forwell’s mold cart systems. These high precision and easy to operate mold cart systems can serve not just one or two injection molding machines but a whole production line at once, making them very efficient and cost effective.

Articles of Injection Molding

TY Die Clamp

- Quick and easy die changing

- Very high clamping pressure

- High opening and closing speeds

- Easy insertion and removal

- Safer Operations

- Increased productivity

As this lever-type clamp does not require a U-slot on the die shoe it can be used in a wide range of applications. The TY type Die Clamps are machined to fit into the T-slot of the bolster for extra secure positioning. The flange-mount model Die Clamps can be bolted onto the bolster and the automatic slider model Die Clamps makes remote automatic operation possible.

Die Clamp Introduction

All Forwell Quick Mold Change Systems use high quality Die Clamps for very secure clamping, quick mold changing and safer operations. These clamps can fasten Molds whether they are changed vertically or horizontally.

There are also a range of different Die Clamps available to suit your injection molding or mold casting requirements. The TY type Die Clamps are machined to fit into the T-slot of the bolster for extra secure positioning. The flange-mount model Die Clamps can be bolted onto the bolster and the automatic slider model Die Clamps makes remote automatic operation possible.

Clamp Specifications

The following specifications can help you choose the appropriate clamp type in accordance with your injection molding requirements and production situation. Make sure of your production plans and production procedure before choosing your product to be sure of the product that best suits your needs.

| Mold Plate | Mold Change Direction | Clamping type | Characteristics |

|---|---|---|---|

| No Union | Vertically | Moving Clamp | Fixed in with T-slot |

| Union | Vertically | Fixed & Moving Clamp | Clamp fixed or Moving on plate |

| Horizontally | Fixed Clamp | Install roller or sliding rail upon the plate. Use cart or mold exchange table for easy operation and the shortest possible mold changing time. |

TY Clamp Model Specifications

| Model | Unit | TY-1 | TY-2 | TY-4 | TY-6 | TY-10 | TY-16 | TY-25 |

|---|---|---|---|---|---|---|---|---|

| Tons Clamping (at 250Kg/cm2) | tons | 1 | 2 | 4 | 6.3 | 10 | 16 | 25 |

| Full Stroke (X) | mm | 6 | 7 | 7 | 8 | 8 | 7 | 8 |

| Clamping Stroke (Y) | mm | 3 | 2 | 3 | 4 | 3 | 3 | 3 |

| Extra Stroke (Z) | mm | 3 | 5 | 4 | 4 | 5 | 4 | 5 |

| Cylinder Capacity st Full Stroke | cc | 2 | 6.5 | 13.2 | 22.3 | 37 | 61 | 93 |

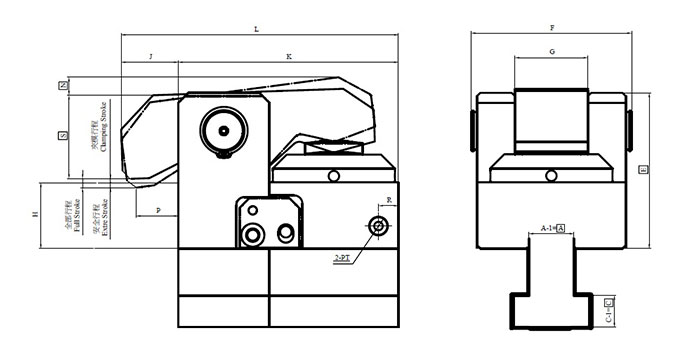

Clamp Dimensions

For a closer look at the exact dimensions of the TY series die clamps please see the following diagram and table.

| Model | min.E | F | G | J | K | L | max.N | P | R | min.S | PT | min.C | min.A |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TY-1 | 49.5 | 46 | 20 | 15 | 58 | 73 | 10 | 10 | 34 | 16.5 | 1/8 | 7 | 10 |

| TY-2 | 59 | 63 | 28 | 22 | 85 | 107 | 10 | 12.5 | 48 | 27 | 1/8 | 9.5 | 12.5 |

| TY-4 | 85 | 87 | 40 | 25 | 120 | 145 | 10 | 16 | 12 | 32 | 1/4 | 12 | 15 |

| TY-6 | 94 | 97 | 44 | 29.5 | 133 | 162.5 | 11 | 20 | 12 | 40 | 1/4 | 14 | 19 |

| TY-10 | 105 | 110 | 50 | 28 | 165 | 193 | 11 | 20 | 19 | 53 | 1/4 | 16.5 | 23 |

| TY-16 | 120 | 130 | 60 | 30 | 200 | 230 | 12 | 20 | 25 | 67 | 1/4 | 19 | 27 |

| TY-25 | 133 | 150 | 73 | 30 | 240 | 270 | 13 | 20 | 30 | 81 | 1/4 | 22 | 32 |

| Model | A | B | C | D | Power Unit Models |

|---|---|---|---|---|---|

| TY-1 | 22 | 37 | 16 | 24 | FP6308U-4-4C |

| TY-2 | 22 | 37 | 16 | 24 | |

| TY-4 | 22 | 37 | 16 | 24 | FP1014U-4-4C |

| TY-6 | 28 | 48 | 20 | 28 | |

| TY-10 | 28 | 48 | 20 | 28 | |

| TY-16 | 28 | 48 | 23 | 28 | |

| TY-25 | 36 | 56 | 25 | 28 |

Die shoe thickness (h) available: 25, 30, 35, 40, 45, 50, 55, 60mm.

Before purchasing, please verify if the mold edge thickness (h) and T-slot (A.B.C.D.) have standard or special dimensions.

Control Panel

- Simplifies Operations

- Easy to use

- Multi Language Interface

- Many automatic functions

- Easy status monitoring

Control Panel Introduction

The easy to use control panel offers a simple interface to monitor and control operations of the Quick Mold Change System. The upper half of the screen displays automatic functions while the lower half can be used for operator-controlled functions. This makes this machine easy to control yet still have the functionality needed of a Quick Mold Change System.

Control Panel Layout Example

.jpg)

Pump Unit

- Very secure and stable clamping

- Pressure can easily be adjusted using an air pressure adjusting valve. Should air pressure become dangerously high, the air pressure will automatically shut off

- Prolonged hydraulic air pressure allows for energy efficient and convenient automated operations

- Hydraulic air pump ensures die clamping even during power cuts or when system pressure drops

Die Clamp Introduction

The hydraulic pump ensures tight and stable die clamping and allows the system to maintain clamping pressure on the mold even when there is a power failure or air pressure drops. The PCB Fine Piercing System uses air-driven hydraulic pumps resulting in very high clamping pressures, high energy efficiency and convenient automated operations. Forwell’s hydraulic pump units also feature an easy to adjust air pressure valve to effectively control the systems air pressure.

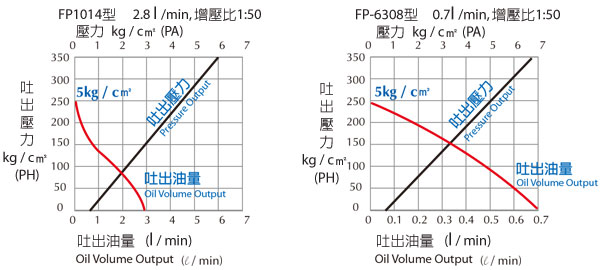

Pump Unit Diagram