Focusing on Screw Fastening for 32 Years, Forwell Accompanys FOXCONN in Agile Manufacturing

2019-03-14

Written by Lin Wei-zhen (林洧楨); Business Weekly 18:04, March 14, 2019

Repeated loosening and fastening of eight screws may make a big benefit of, say, an annual turnover of 500 million NTD. How can it be and who makes it happen?

In Puxin, hanghua, there is a machinery supplier who clings to the automation trend by mastering the screw fastening technology; shortening the 4 hour mold and die change procedure to an instant 3 minutes instead. This automation technology attracts the eyes of FOXCOON, AUO, Haier, GREE, KONKA, and many other international companies cross strait. Currently, the system owner works to keep up with the trend of Industry 4.0, rendering 5 time as much as its revenue for the past seven years, and becomes the leading brand of quick mold and die change system in Taiwan and China.

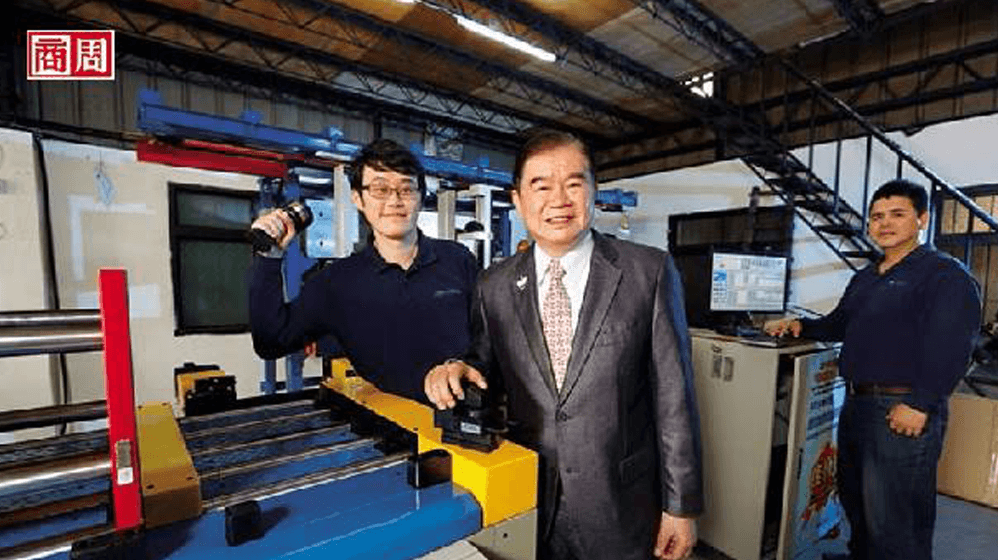

The name of the company is Forwell, and President Hsiao Wen-long is the man behind of wheel.

Poor farmer becomes leaders in the mold and die changing sector

Hsiao Wenlong said that his chance of success stems from the growth of his insights when he was admitted to KENDA Tire Factory in his early years. He was a poor-born son of farmers, while with his diligence, his monthly salary escalated from 7,000 NTD as a technician, to 40,000 NTD as the new manager of design dept that is responsible of the planning of new production lines. With this change, he also had the opportunity to participate in countries with advanced technology, such as Japan, to see the world about the latest automation technology in the automotive industry. "All sectors in the industry are the same, and automation is the way to go." He realized this trend 30 years ago and decided to start his business.

At that time, he witnessed the mold replacement process of the plastic injection molding factory. Because the accuracy of the mold positioning was related to the product yield rates, so all the manuals such as the simple release and the locking action are all based on senior employees’ sense of feeling. During the mold replacement, the machine was shut down for more than 4 hours. Hsiao recognized that it is the change for him and decided to invest in the automatic quick change system.

Chen Kun-qi(陳錕淇), the person in charge of Baihong Machinery (百宏機械), has invested in the mold change system in the early years. He pointed out that in the early days who understand the mold details do not understand automation; while those who understand automation does not understand the details of molds; therefore the background that President Hsiao has integrates both the mechanical knowledge and the tire automation production line, and eventually makes Hsiao an exclusive one in the market. Meanwhile, at the same price, the system developed by competitors is mostly a manually positioned clamp, and Hsiao’s product can be automatically positioned with just one button. What's more is, at that time, the market order volume was so confined, and most of the others opened stores aiming certain products while sold the quick changeover equipment as a part time job, while Xiao Wenlong began hisquick change model store from the very beginning.

Going beyond the trend but losing money for 5 years

Being confident about the products, Hsiao encountered serious difficulty because the idea of automation is rarely recognized by Taiwanese people as important at the time in the 1980s. People then were busy at delivery for their goods as the economy was very good and business owners didn’t even have the time for facility upgrade. What’s even more was, the cost of manpower then was comparatively low so that the need for automation was not urgent, and for product manufacturing the model was still mass production of single item, so that the need to change molds and dies is relatively less-frequent. For the first five years of the establishment of Forwell, the company lost a lot of capitals and all the shareholders left but only Hsiao remained.

Confronted by the market situation, President Hsiao lived a life of austerity by selling the products at daytime and planning the products at nighttime. He works and do many jobs by himself and keep the minimum cost by hiring only 10 people. Even if the days were so stern, Hsiao still believed that automation is the right direction. Honorary director of TAMI, Mr. Xu, Xiu-cang (徐秀滄) said that, Hsiao is much professional than others and is more persistent than others as well.

The idea of 1% for capital goods helps Taiwanese to the China’s market

Secretary general Mr. Wang, Zheng-qing (王正青) still remember that at that time, the only strategy for Hsiao is to educate his customers. So he spent millions of his earnings on the exhibition business as well as promotions. Therefore, in 1997, people from FOXCONN noticed Forwell and contacted them for cooperation. At the same year, it is the 1997 Asian Financial Crisis, many Taiwanese suppliers were forced to move their plants to China, and Forwell took the change to turn its fate.

Competitors analyzed that, Forwell’s clamp devices cost around 200,000 NTD, covering no more than 1% of the capital goods investment, yet can shorten the mold and die change time from hour to minute. This practical issue is one of the critical reasons that FOXCONN chose Forwell when they go to the China market.

With the orders made from FOXCONN, Forwell’s market value raised in a large scale and since then it has expanded successfully; now more than half Taiwan’s suppliers in China adopt Forwell’s mold or die change system. GM Hsiao, who is the son of President Hsiao, said that at the very beginning his father foretold the trend as he noticed that conventional factories haphazard put molds and dies everywhere and whenever they need some specific ones they seek it based on their memories. With the idea inspired by the retailers, Hsiao has developed his direction.

Extended service appraised by customers

President Hsiao still remember the memory that goes beyond the trend too far, so he keeps his pace steady and his business scale within 100 million NTD. In the year 2013, the idea of Industry 4.0 was emerged from Germany and the trend of small quantity but diversified types are thus consolidated, so Hsiao invested a lot to build a plant in Huai’an, China with the amount of his three year revenue. The Huai’an plant aims at automatic carry cart and automatic mold/ die warehousing system. One set of the system cost at least 5 million NTD.

Walking into the factory of Forwell, you can see a large mold/ die warehouse, and the automatic cart moves in and out to take molds and dies out and in, carrying them to the production lines. With a single bottom, 8 clamps works accurately and automatically within three minutes without the manual operation. This productivity is suitable for diversified but small amount manufacturing models. Some large groups such as FOXCONN is talking with Forwell about the introduction of this system.

With hundreds of patents registered in Taiwan and China, Forwell has a threshold that protects its market. However, business insiders Mr. Zeng, Din-chen (曾定宸) in the SEYI said that, the know-how in this field has been acquired gradually by people, so Forwell still has to work hard steadily in order to compete with Japanese and German competition, while leave the competition with the Chinese competitors. And the key is Hsiao’s speed of moving forward.

●Name: Forwell

Established: 1987

President: Hsiao, Wen-long (蕭文龍)

GM: Hsiao, Bi-cheng (蕭皕成)

Product Inventory: Clamping device, automatic cart, mold & die warehouse, and automatic mold & die change system

Achievement: Revenues in 2018 was about 500 million NTD

Status: Leading brand of QDCS & QMCS in Taiwan and China

Article source: https://today.line.me/TW/pc/article/M2k2GM?utm_source=lineshare